Grain Processing

Grains arriving in the mill usually contain foreign matter, such as strings, straw, parts of bags, wood, stones, or metal that must be removed before processing. The contaminants usually become mixed with the grains in the field and during its transfer through the various stages of the grain processing and grain-handling system. In addition, grains always contain some seeds of other plants, even if grown under the best conditions. If farming or environment conditions are poor, the amount of screenings is likely to increase. Although part of the foreign material (dockage), or all of it, is discounted in the trade, the cleaning system in the mill should be designed to allow the miller enough flexibility to properly clean any Grains arriving at the mill.

The CLEANING SECTION is subdivided into-

- Intake – Incoming Grains is weighed, sampled and analyzed.

- Pre Cleaning – Upon arrival, the Grains are pre-cleaned with a high-capacity system to separate coarse foreign material, ferrous particles, and dust and to prepare the Grains for storage and safe handling.

- 1st Cleaning – Major Cleaning ends at dampening or washing

- Conditioning or Tempering – To prepare Grains in the same state of mellowness for same grinding conditions

- 2nd Cleaning – To remove any impurities left over in previous cleaning system

To make effective cleaning we need proper cleaning machines for getting the best results. Customer can find suitable machine for every need from our vast range of grain processing machines.

SPECIFICATIONS*

- Reel machine is an ideal machine for pre cleaning purpose.

- Available in various sizes (2 sieves, 3 sieve & 4 sieve with sieve cleaning brush)

- This machine is used to separate out fine and large size impurities

| FEATURES | 2 SEIVE | 3 SEIVE | 4 SEIVE |

| ITEM NO. | S940 | S965 | S986 |

| TECHNICAL SPECIFICATIONS | |||

|---|---|---|---|

| MODEL | LENGTH | WIDTH | HEIGHT | CAP/TON/HR | POWER/KW | AIR QTY |

|---|---|---|---|---|---|---|

| 2 SEIVE | 2300 | 820 MM | 1220 MM | 2-3 | 2 | 5M3/MIN |

| 3 SEIVE | 3440 | 1070 MM | 1820 MM | 4-6 | 3 | 10M3/MIN |

| 4 SEIVE | 4350 | 1070 MM | 1820 MM | 8-10 | 5 | 10M3/MIN |

SPECIFICATIONS*

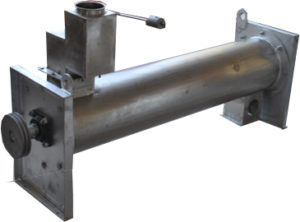

- This is an ideal machine used for de -hulling of wheat & other grains

- Highly sophisticated

- Mostly used in whole meal Atta plant and Dal plant

- The processing effect of the machine can be adjusted from outside by means of slide control device.

| FEATURES | 12"x30" | 14"X33" | 16"X33" |

| ITEM NO. | S765 | S988 | S766 |

| TECHNICAL SPECIFICATIONS | ||||||

|---|---|---|---|---|---|---|

| MODEL | LENGTH | WIDTH | HEIGHT | CAP/TON/HR | POWER/KW | AIR QTY |

| SVER-1 12"x30" | 1570mm | 500MM | 700MM | 1-1-5 | 7.5 | 15-20M3/MIN |

| SVCS-1 14"x33" | 1730mm | 650MM | 1100MM | 1-1-5 | 7.5 | 15-20M3/MIN |

| SVER-1 16"x33" | 2100 MM | 750 MM | 1200 MM | 3-3-5 | 15-20 | 35-40M3/MIN |

SPECIFICATIONS*

- This is an ideal machine used to for de-hulling of wheat & other grains

- Highly sophisticated

- This machine is mostly used in whole meal Atta plant and Dal plant

- The processing effect of the machine can be adjusted from outside by means of slide control device.

| FEATURES | SVVAC 100 | SVVAC 150 | SVDAC 100 | SVDAC 150 | |

| ITEM NO. | S849 | S977 | S781 | S782 | |

| TECHNICAL SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| TYPE | SVVAC 100 | SVVAC 150 | SVDAC 100 | SVDAC 150 | |

| Air flue width(mm) | 1050 | 1520 | 1059 | 1520 | |

| Air flue thickness (mm) | 200/300 | 200/300 | 200/300 | 200/300 | |

| Air Pressure(mm H2O) | 50 | 60 | 50 | 60 | |

| Air Volume (m3/min) | 52-90 | 80-135 | 52-90 | 80-135 | |

| Dimension (mm) LxWxH | 1020x200/300x1450 | 1520x200/300x1450 | |||