Grain Handling

Grain Handling or Conveying Equipment

Grain Conveyors and Elevators

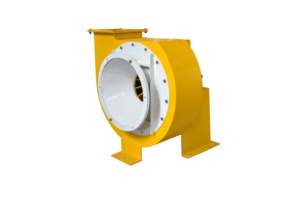

Grains will be unloaded in the feed hopper manually. Grating is provided in the feed hopper to avoid large size impurities. Suction hood is provided on the feed hopper to extract dust generated during grain unloading. The material will be conveyed by screw conveyor to bucket elevator, which discharges the grain into pre-cleaner. The pre-cleaner is for size separation and cleaning of grain. Cleaned grains are conveyed to storage silo through bucket elevator and chain conveyor. A dust extraction system comprising of bag filter, centrifugal fan, rotary valve is provided in this section. Bag filter separates dust, and discharges clean air in the atmosphere. Pulse jet type cleaning mechanism is incorporated in the bag filter, which ensures the bags are cleaned at specified time interval.

Pneumatic conveying System

The pneumatic conveying system is a method of conveying dry material in a pipeline through air without any moving parts. The pneumatic conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Each pneumatic conveying system is designed & customized as per the application popularly known as custom conveyor system. The provided solution is assured to be the best pneumatic conveying system solution for the application. Being the application experts & pneumatic conveying system manufacturer, we always assure to deliver best of both the worlds (commercial & technical worlds).

SPECIFICATIONS*

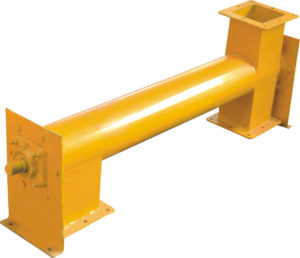

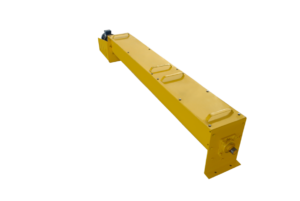

- Screw Feeder is used for continuous feeding of matiral into bins & silos.

- Machine is used as a capacity fixing device.

- Conical Hopper and Stand.

- VFD conttolled Screw feeder with .5.H.P Helical Geared Motor.

- Grain Empty level Sensor for Tripping of Mill's Motor and Feeding.

- Alarm for Level control.

- Control Panel for Sensor and VFD and alarm.

| FEATURES | SGVF-1 | SGVF-2 | SGVF-3 | SGVF-4 | |

| ITEM NO. | S824 | S774 | S775 | S776 | |

| TECHNICAL SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| LENGTH | WIDTH | HEIGHT | CAP/TON/HR | POWER/HP | |

| SGVF-1 | 500 MM | Dia 100 mm | 450 mm | 1Ton/Hr | .50 |

| SGVF-2 | 500 MM | Dia 160 mm | 450 mm | 2Ton/Hr | 1 |

| SGVF-3 | 1000 MM | Dia 100 mm | 450 mm | 1Ton/Hr | 1 |

| SGVF-4 | 1000 MM | Dia 160 mm | 450 mm | 2Ton/Hr | 1.5 |